| Model |

KRYCH-15W

KRYCH-15 |

| Temp Control |

-40℃~135℃ Antifreeze |

-45℃~100℃ Test chamber |

| Antifreeze flow control |

2L/min~20L/min ±0.2L/min |

| Antifreeze pressure |

Measure and display the inlet and outlet pressure and display the pressure on the touch screen |

| Test chamber volume cm |

100*100*100 1m3 |

| Heating Power |

7.5kW Antifreeze |

5kW Test chamber |

Refrigeration capacity

Antifreeze |

135℃ |

7.5kW |

| 20℃ |

7.5kW |

| 0℃ |

7.5kW |

| -20℃ |

4.5kW |

| -30℃ |

2.5kW |

| -35℃ |

1.8kW |

Refrigeration capacity

Test chamber |

100℃ |

6kW |

| -20℃ |

3.5kW |

| -40℃ |

1.2kW |

| Antifreeze temp. control accuracy |

±0.3℃ |

| High & low tempe chamber Tempe control |

±0.3℃ |

| Circulating air inside the test chamber |

3500m3/h |

| When the door is opened, the internal circulation fan automatically turns off, and the door-opening status is displayed on the touch screen. |

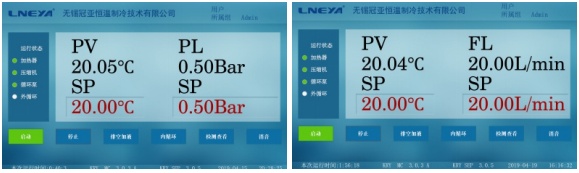

| Controller |

PLC controller, fuzzy PID control algorithm |

| Letter of agreement |

Ethernet interface TCP/IP protocol |

| Device internal temperature feedback |

Internal temperature of the equipment tank, condensation temperature of the refrigeration system, compressor suction temperature, cooling water temperature (for water cooling equipment) |

| Heating |

Refers to the maximum heating output power of the system (according to each model)

The heater has triple protection and an independent temperature limiter to ensure the safety of the heating system

The heating power of 15kW uses a voltage regulator, and the heating power output control adopts 4~20mA linear control. |

| Cooling capacity |

It refers to the ability to take away heat at different temperatures (under ideal conditions). Actual working conditions need to consider environmental heat dissipation. Please amplify appropriately and take insulation measures. |

| High temperature cooling module |

Can cool down module from high temperature 150℃ |

| Circulation pump flow and pressure |

Using LNEYA magnetic drive pump |

| Source 380V50HZ |

23kW max |

| Overall dimensions cm |

125*235*190 excluding protruding parts, air-cooled and water-cooled have the same dimensions |

| Compressor |

Emerson Copeland Scroll Flexible Compressor |

| Evaporator |

Plate heat exchanger |

| Refrigeration accessories |

Emerson/Danfoss brand filter dryers, oil separators, etc. |

| Throttle method |

Electronic expansion valve |

| Operation panel |

7-inch color touch screen, temperature curve display\EXCEL data export |

| Security |

It has self-diagnosis function; phase sequence phase failure protector, refrigerator overload protection; high-voltage pressure switch, overload relay, thermal protection device and other safety protection functions. |

| Refrigerant |

R-404A/R507C |

| Antifreeze interface is reserved inside the chamber |

ZG3/4 and switch valve |

| Water coooling W |

Models with W are water-cooled |

| Water cooled condenser |

Casing heat exchanger |

| Cooling water 32℃ |

6m³/H |

| Shell material |

Cold rolled plate spraying (standard color 7035) |

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA