SEMICONDUCTOR COOLING CHILLERS

Single channel & Dual channel chiller Temp control range -80℃~225℃

Outdoor chiller unit or Indoor chiller unit

In the semiconductor manufacturing process, in addition to the mentioned equipment, there are many links that require the support of chillers to ensure temperature control and the accuracy of the process. For example, oxidation/diffusion, photolithography, etching, ion implantation, thin film growth, polishing, used on semiconductor heat sinks, for probe stations, and controlling probe station chuck temperature.

LNEYA temperature control equipment has high precision, intelligent temperature control, and a wide temperature control range, ranging from -100 ℃ to 90 ℃, suitable for the constant temperature control needs of most enterprises. The temperature control accuracy can reach ± 0.05 ℃.

Process Water Chiller

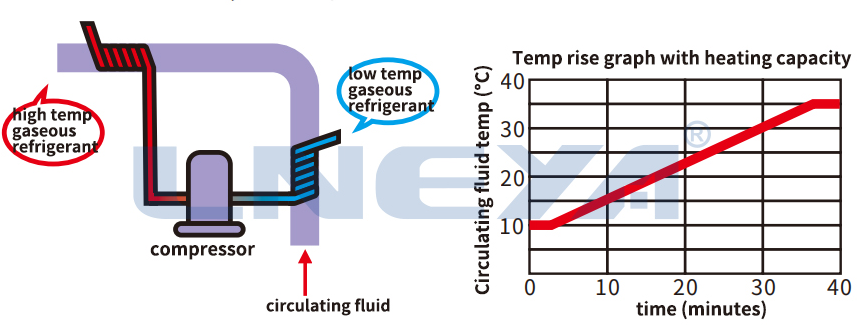

Heating within 40 ℃ by the hot air of the gas extraction compressor.

The Chiller circulation system adopts a fully enclosed design and uses a magnetic driven pump.

Chiller 100% helium testing, 100% safety compliance testing to ensure safety and reliability.

Chiller 100% continuous operation of the copying machine after 24 hours

- More

Double Frequency Conversion FLTZ -30℃~40℃

Temperture accuracy ±0.1℃ Flow control 15~45/min 6bar max

- More

Low Temp Series FLT -100℃~80℃

Temperture accuracy ±0.1℃ Flow control 25~75/min 6bar max

- More

Conventional Type FLT -45℃~80℃

Temperature control in semiconductor production and testing processesEnsure stable and reliable overall semiconductor process flow from front-end to back-endProduct’s Descriptionchillers that control the processing temperature on the Fab equipment…

- More

Heat Exchange Chiller ETCU +5℃~90℃

Temperature control in semiconductor production and testing processesEnsure stable and reliable overall semiconductor process flow from front-end to back-endProduct’s DescriptionApplication scenarios of temperature control in semiconductor process…

loading…

已经是到最后一篇内容了!

| Model | Type | Temp Control Range | Temp Control Accuracy | Cooling Capacity | Multi-channel |

| FLT Series | Water cooling | -45℃~90℃ | ±0.05℃ | 1kw~40kw | Multi channel |

| FLT Series | Water cooling | -100℃~80℃ | ±0.05℃ | 1.5kw~3kw | Single channel |

| FLTZ Series | Water cooling | -30℃~40℃ | ±0.05℃ | 11kw | Single channel |

| ETCU Series | Water cooling | 5℃~90℃ | ±0.05℃ | 5kw~300kw | Single channel |

Air Cooling Chiller

Temperature control range: -110 ℃ to -40 ℃

Air volume range: 15m ³/ H~100m ³/ H

Efforts should be made to cool down the corrosion of materials, such as dry compressed air, nitrogen gas, argon gas, etc., and introduce them into the LQ series equipment at room temperature. The resulting materials can reach the standard low temperature and be supplied to the components or heat exchangers for demand testing.

- More

LQ -40°C~-110°C

Heating Power 2.5kW~25kW Cooling capacity 0.25kW~25kW Power range 6.5kW~50kW

loading…

已经是到最后一篇内容了!

Temperature Forcing System

Temperature control range: -120 ℃ to+300 ℃

The temperature rise and fall rate is very fast, with a Temperature range of 150 ℃ to -55 ℃<10 seconds, and a maximum flow rate of 30m ³/ H;

Real time monitoring of the actual temperature of the tested IC, achieving closed-loop feedback

- More

AES -115℃~225℃

Cooling water 0.6m³/h~3m³/h Power range 3.7kW~7.5kW

loading…

已经是到最后一篇内容了!

Thermal Chuck & Thermostat

Equipped with a cooler, it avoids the consumption of liquid nitrogen, carbon dioxide, etc. Each system includes a chuck and a cold and hot control unit;

Fast temperature rise and fall, constant temperature control, suitable for testing RF devices and high-density power devices

- More

MD -75℃~225℃

Temperture accuracy ±0.1℃ Source Power 2.8KW

loading…

已经是到最后一篇内容了!

waste gas recovery Condensing Unit (VOCs)

Gas condensation liquefaction recovery

Connect the waste water to the equipment through a suction fan, and collect and separate it into a collection tank by reducing the temperature for liquefaction, while discharging other materials;

The condensation recovery process requires cooling the fluoride waste gas below its dew point to condense it into a liquid for easy collection and treatment. A chiller is a device that can provide low-temperature cooling, which can cool fluoride waste gas to a suitable temperature, thereby promoting the smooth condensation process.

- More

YQH 0℃~-75℃

exhaust gas subber

loading…

已经是到最后一篇内容了!

Applications

- Cooling photolithography, dry etching

- Cooling the furnace body and walls

- Cooling CVD reaction chambers and equipment

- Cooling targets and PVD equipment

- Cooling ion implantation equipment

- Cool the grinding disc and equipment

- Cooling probe table, grinding disc and equipment

- Cooling packaging equipment and mold

- Fluoride waste gas condensation recovery

chiller for semiconductor company

chiller with IC tester

chiller with chip aging dryer

chiller for Material manufacturing testing

Which process are you looking for chiller?

Different models are tailored to different processes

Please leave your process temperature control requirements here

Advantages

Condenser: micro-channel heat exchanger (air-cooled)plate heat exchanger (water-cooled)

Control system: PLC programmable controller

Communication: RS485 interface Modbus RTU protocol/ Ethernet interface TCP/lP protocol

Shell material: cold-rolled plate spray RAL7035lnsidethe pipeline: stainless steel SUS304,copper, ceramics,silicon carbide,silicone sealant, PTFE

Serial Communication

Remote operation signal input

Alarm, Running status, Signal output

Heating function

Due to the use of heat generated during heating, circulating heating can be achieved without the need for a heater.

Chillers Heaters for Other Industry

Chillers (Biochemistry Pharmaceutical Process)

Normal Temp/ Low Temp/ Ultra Low Temperature

Water Cooling/ Air Cooling

Power 0.5kW~2000kW

Industries such as biochemical pharmaceuticals, petrochemicals, semiconductors, and automobiles

Reactors, distillation systems, extraction systems, AOI systems, testing chambers etc.

Dynamic Temperature Control Systems (Biochemistry Pharmaceutical Process)

Temperature Control :-120℃~350℃

Temperature control for high pressure reactor;Double-layer glass reactor;Double-layer reactor;Microchannel Reactor;Distillation system;Material aging test;Vacuum chamber etc.

Control Temperature Control Flow Systems(Vehicle/Battery Pack Test)

Temperature Control: -40℃~100℃

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

LNEYA’s industrial chiller cooling equipment is sold globally. Singapore, Malaysia, Japan, South Korea, various European countries such as Germany, Netherlands, UK, and United States, India.

Customized Semiconductor chiller

(LNEYA’s chiller supports both indoor and outdoor options.)

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA