CHILLERS

For industiral, pharmaceutical, battery, semiconductor

Various types of chillers are available to meet your efficiency and goals

INDUSTRIAL PROCESS CHILLERS WITH GOBAL SERVICE SUPPORT

(LNEYA’s chiller supports both indoor and outdoor options.)

Laboratory/Industrial Water Chillers

-18℃~50℃

Can be used for cooling the heating part of the semiconductor manufacturing device, cooling the heating part of the laser device, and cooling the heating part of the analysis and detection machine.

|

Model

|

Type

|

Cooling Capacity

|

Temp Control Accuracy

|

| LT 5℃~50℃ |

Water-cooling

|

1.5kW~17kW

|

±0.1℃

|

|

Water-cooling

|

0.9kW

|

±0.5℃

|

Low Temperature Refrigeration Chiller

Widely used in high-tech industries such as petrochemical, medical, pharmaceutical, biochemical, freeze-drying, pharmaceutical and so on.

| Model | Type | Cooling Capacity | Power |

| LX -25℃~30℃ | Air-cooled | 0.8kW~30kW | 1.5kW~17kW |

| LT -45℃~30℃ | Air-cooled | 0.75kW~12kW | 1.6kW~8kW |

| LT -60℃~-20℃ | Air-cooled | 0.4kW~6kW | 3kW~9kW |

| LT -80℃~-20℃ | Air-cooled | 0.2kW~6kW | 3.5kW~11.5kW |

| LT -115℃~-70℃ | Water-cooled | 0.3kW~2.1kW | 5.5kW~14kW |

Cryogenic Water Cooled Chillers

Widely used in chemical, pharmaceutical, biochemical and other industries in the field of low temperature reaction, refrigeration speed, safety and reliability.

| Model | Type | Cooling Capacity | Power |

| LJ -45℃~-10℃ | Water-cooled | 6kW~180kW | 14kW~270kW |

| LN -60℃~-10℃ | Water-cooled | 6kW~180kW | 16kW~300kW |

| LD -80℃~-30℃ | Water-cooled | 4kW~180kW | 24kW~588kW |

| SLJ -110℃~-150℃ | Air-cooled | 2.5kW~11kW | 12kW~36kW |

| CDLJ -110℃~-50℃ | Water-cooled | 2kW~120kW | 16kW~768kW |

Semiconductor Testing Chillers

Chiller 100% helium testing, 100% safety compliance testing to ensure safety and reliability.

Chiller 100% continuous operation of the copying machine after 24 hours.

|

Model

|

Type

|

Cooling Capacity

|

Temp Control Accuracy

|

| FLTZ -30℃~40℃ |

Water-cooling

|

2.5kW~11kW

|

±0.05℃

|

|

Water-cooling

|

0.6kW~3kW

|

±0.05℃

|

|

|

Water-cooling

|

1kW~8kW

|

±0.05℃

|

|

|

Water-cooling

|

5kW~13kW

|

±0.2℃

|

Vehicle / Battery Testing Chillers

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

|

Model

|

Type

|

Cooling Capacity

|

Temp Control Accuracy

|

| KRY -40℃~100℃ 1 with 1 |

Water&Air Cooling |

1.2kW~60kW

|

±0.5℃

|

|

Water&Air Cooling

|

2.5kW~60kW

|

±0.5℃

|

|

|

Water-cooling

|

4kW~60kW

|

±0.5℃

|

|

|

Water-cooling

|

5kW~60kW

|

±0.5℃

|

Applications

| Reaction kettle | Fermentation tank | Microreactor | Tubular reactor |

| Vacuum chamber | Freeze-drying machine | Multiphase reactor | Tower reactor |

| Industrial oil treatment | Gas chromatograph | Rotary evaporator | Pilot plant |

| Injection water system | Pharmaceutical water system | Neutralization reaction | decomposition reaction |

| oxidation reaction | Polymerization reaction | Crystallization reaction | Fermentation reaction |

| Oil decomposition | Concentration reaction | Extraction System | Test Bench |

| Gas Condensation | Semiconductor Testing equipment | Fab equipment | AOI system CMOS/CCD |

| Tool machine | Cooling tower | Battery test cooling | Laboratogy research |

Air Cooling /Cooled Chiller

- Does not need to be connected to the cooling tower and is suitable for environments with low impurity content. Impurities can easily mix in the cold water tower, and dust can cause blockage in the cooling water circulation circuit, leading to a decrease in cooling capacity.

- The air-cooled chiller is most suitable for areas with poor water quality, which can save other accessories such as cold water towers.

- The use of large capacity condensers makes operation easier and more convenient.

- The footprint is greatly reduced, making installation very convenient.

- The air-cooled chiller unit adopts an upper air outlet design.

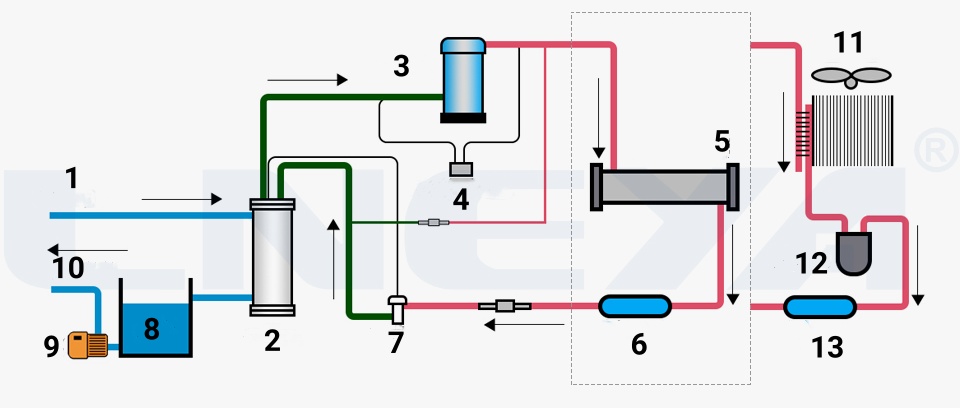

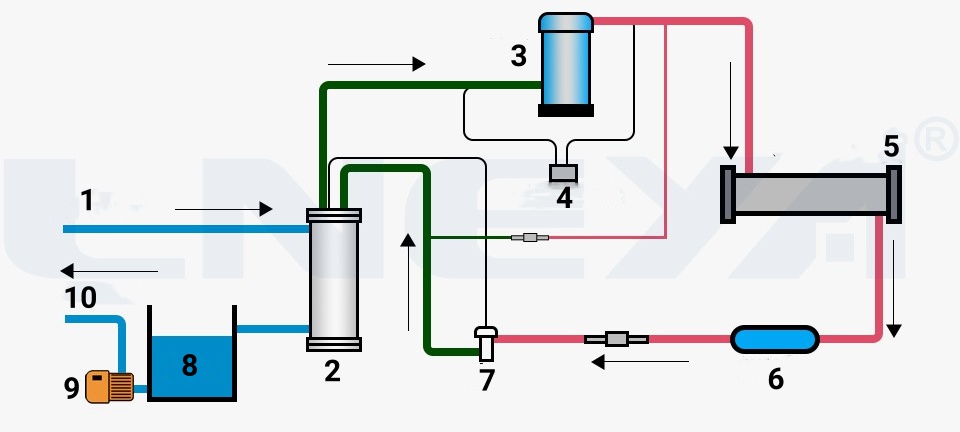

Water Cooling/Cooled Chiller

- The water-cooled condenser adopts the latest high-efficiency externally threaded copper pipes, which have a large heat dissipation capacity. It adopts the latest CAD/CAM processing technology and is manufactured in cooperation with CNC machining centers, with a compact structure, high efficiency, and energy saving.

- Industrial chiller unit configuration: equipped with a microcontroller control system, built-in compressor dryer filter and expansion valve, maintenance manual valve interface and other devices, ensuring reliable and safe operation of the machine and convenient maintenance.

- The multifunctional operation panel of the industrial chiller unit is equipped with an ammeter, control system fuse, compressor on/off button, water pump on/off button, electronic temperature controller, various safety and security fault lights, as well as unit startup and operation indicator lights, making it easy to operate and use.

Customer Applications

For Distillation rack

For Pharmaceutical

For Vehicle test chamber

For Reaction tank

For Quality testing

For Emulsification kettle

For Quality testing

For Water tank

LNEYA’s industrial chiller cooling equipment is sold globally. Singapore, Malaysia, Japan, South Korea, Australia, various European countries such as Germany, Netherlands, UK, United States, Belgium, Czech Republic, Netherlands, France,India and Qatar etc.

Why Choose LNEYA?

Customized Chillers

Not all chiller heaters are created equal. Come see why!

Submit your chiller intentions and requirements, Get chiller solutions and quotes

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA