Vehicle-mounted OBC Test Chiller/Thermal Control Unit

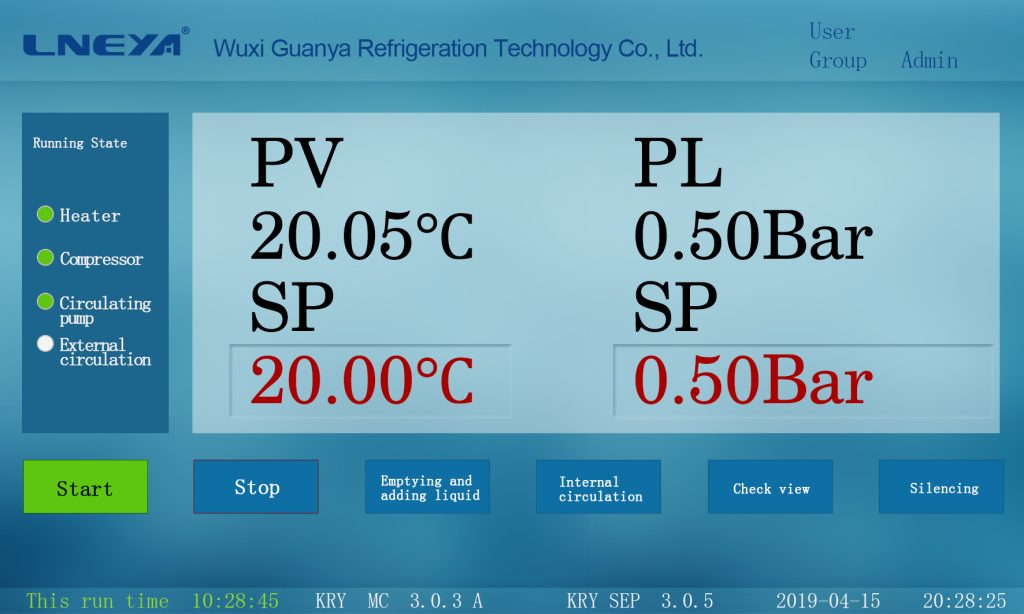

KRY 0℃~100℃ 1&2S- Heating Power10kW~38kW

- Cooling capacity7kW~60kW

- Power range17kW~65kW

- Temperature accuracy±0.5℃

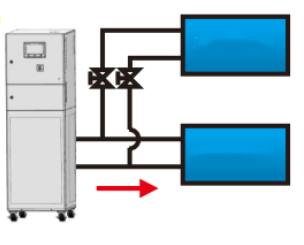

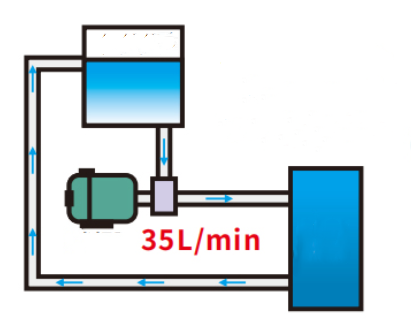

- Flow rate output2~50 L/min

- RefrigerantR404A/R507C/R125/N40

- Weight360KG~1700KG

Description

Parameters

Quotation

Recommended Products

SUNDI -80℃~250℃

Heating Power 3kW~80kW Cooling capacity 0.3kW~80kW Power range 7.5kW~150kW

ZLF -45℃~250℃

Heating Power 25kW~80kW Power range 2.3kW~10.5kW Material accuracy ±1℃

SUNDI -60℃~250℃

Cooling capacity 0.25kW~60kW Heating Power 2.5kW~60kW Power range 5kW~95kW

SUNDI -25℃~200℃

Cooling capacity 1kW~200kW Heating Power 2.5kW~200kW Power range 4kW~260kW

loading…

已经是到最后一篇内容了!

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA