BMS Cooling Chiller & Hydrogen Chiller

KRY -40℃~100℃ 1&1- Heating Power5.5kW~60kW

- Cooling capacity1.2kW~60kW

- Power range10kW~84kW

- Temperature accuracy±0.5℃

- Flow rate output1~40 L/min

- RefrigerantR404A/R507C

- Weight250KG~1300KG

CAN BE CONTROL TEMPERATURE AND FLOW

Temperature control of new energy vehicle components testing

Refrigeration, heating, temperature control, flow control

Connect the tested object to a testing platform adapter

The components are cooled and heated internally through ethylene glycol aqueous solution for testing.

-40 ℃~100 ℃ (can be extended to 150 ° C)

Product’s Description

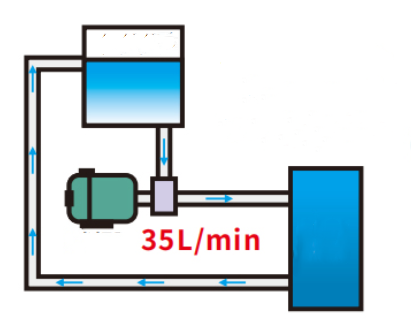

Equipped with a powerful circulation pump while ensuring the delivery of highly viscous liquids.

Control the flow output with variable frequency regulation or proportional control valve to achieve high precision control total range 5%~100% adjustment.

General equipment

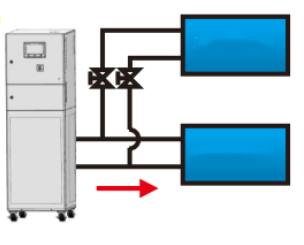

Multichannel equipment

Temperature range is -40℃~+100℃, which can be extended to +135℃ according to the actual situation, and the temperature control accuracy is plus or minus 0.5℃. The equipment can control the flow and pressure independently while controlling the temperature, and different customized solutions are required for simultaneous control.

The tested object is attached to a test platform adapter.

The inside of the part was cooled and heated by an aqueous solution of ethylene glycol.

The test component needs to go through a specific temperature profile and record changes in temperature.

Temperature variations typically range from -40 ℃to 100 ℃. (expandable to 150 ℃)

When performing a tolerance test, it usually takes an infinite loop.

Multi channel independent temperature control

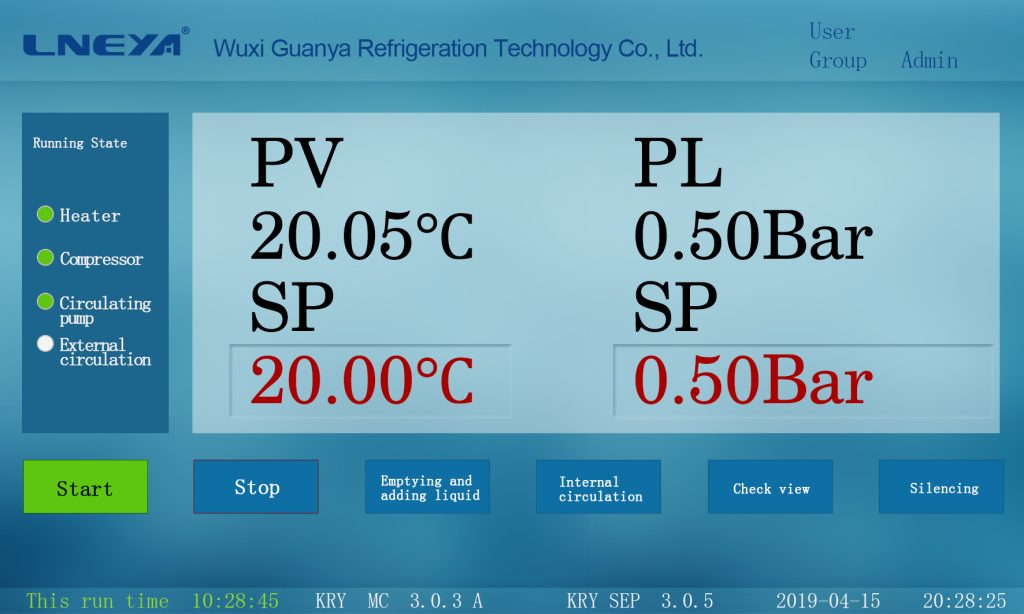

The system adopts LNEYA PLC control, with simple menu navigation, a 7 inch color large screen, and comprehensive and multifunctional image display of important data information. The newly added safety measures ensure continuous unmanned operation. All relevant operating status data is continuously monitored and visualized on the touch screen. It supports independent control of one to many channels, and each group can be set independently.

Variable frequency regulation

The variable frequency pump can adjust the circulating liquid pressure and flow rate, achieving high-precision control of 5%~100% of the total range adjustment.

Client A

Client B

By using a variable frequency pump, the motor speed can be controlled at the appropriate value corresponding to the required pressure.

Applications

Chillers play a key role in multiple processes to ensure temperature control, improve production efficiency and ensure product quality during production. The following are several key processes in lithium battery manufacturing that require chillers:

- Chillers can ensure that the temperature of the slurry is controlled within an appropriate range during the mixing process to avoid degradation of the slurry performance due to excessive temperature.

- Chillers help control the temperature of the coating machine to ensure the viscosity and fluidity of the slurry during the coating process, thereby improving the uniformity and quality of the coating.

- Chillers can control the temperature and humidity in the drying chamber to ensure the efficiency of the drying process and the stability of the slurry.

- Chillers can help control the temperature of the winding machine or stacking machine to ensure the quality of the battery core or battery stack.

- Chillers can accurately control the temperature in the formation cabinet to ensure the formation effect and safety of the battery.

- Chillers can ensure that the temperature in the sub-capacity cabinet is controlled within an appropriate range to obtain accurate test results.

- Chillers can control the temperature in the aging chamber to simulate different usage environments and evaluate the aging performance of the battery.

- PACK assembly: The refrigerator can control the temperature of the assembly workshop to ensure the stability of batteries and components during the assembly process.

- Performance testing: The refrigerator can provide precise temperature control to ensure the accuracy and consistency of test results.

Temperature simulation for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc. It can simulate the external environmental conditions in the climate chamber or replace the internal system, which can create the necessary actual temperature conditions for the test bench.

Motor and motor controller

Motor coroller durabilitytest, motor and motorcontroller bracket

Charge point test

On load charging experiment and charging communication interactive test

OBC/DC-DC

Model test, power test. Durability test

Power battery system

Battery pack charge and discharge test, fuel cell test

Multi-channel Chillers

KRY -40℃~100℃ 1 with 6S

Heating Power 15kW~38kW Cooling capacity 10kW~60kW Power range 36kW~8kW

KRY -40℃~100℃ 1 with 3S

Heating Power 15kW~38kW Cooling capacity 4kW~60kW Power range 23.5kW~82kW

KRY -40℃~100℃ 1 with 2S

Heating Power 10kW~38kW Cooling capacity 2.5kW~60kW Power range 17kW~81kW

loading…

已经是到最后一篇内容了!

| Model | Synbol Unit | KRY-455/455W | KRY-475 | KRY-4A10/4A10W | KRY-4A15/4A15W | KRY-4A25/4A25W | KRY-4A38W | KRY-4A60W |

| Temp Range | ℃ | -40℃~+100℃ | ||||||

| Flow rate output | L/min | 1~10 L/min | 1~25 L/min | 1~25 L/min | 1~40 L/min | 1~40 L/min | 5~50 L/min | 5~50L/min |

| Flow rate accuracy | L/min | ±0.2 L/min | ||||||

| Heating power | kW | 5.5kW | 7.5kW | 10kW | 10kW/Optional 15kW | 15kW/Optional 25kW | 25kW/Optional 38kW | 38kW/Optional 60kW |

| Cooling Capacity | 100℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW |

| 200℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| 0℃ | 5.5kW | 7.5kW | 10kW | 15kW | 25kW | 38kW | 60kW | |

| -35℃ | 1.2kW | 1.8kW | 2.5kW | 4kW | 6.5kW | 10kW | 15kW | |

| Refrigerant | R404A/ R507C | |||||||

| Power 380V50HZ | kW max | 12kW max | 15kW max | 20kW max | 29kW max | 42kW max | 58kW max | 84kW max |

| Dimension(W) cm | (W) cm | 55*95*175 | 55*95*175 | 55*95*175 | 70*100*175 | 80*120*185 | 100*150*185 | 145*205*205 |

| Dimension(A) cm | (A) cm | 55*95*175 | 55*95*175 | 70*100*175 | 80*120*185 | 100*150*185 | ||

|

Weight (water cooling) |

KG | 250KG | 280KG | 320KG | 360KG | 620KG | 890KG | 1300KG |

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | ||||||||

| Temp. control | Process temp. control and jacket temp. control model | ||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | ||||||||

| Program Editor | 10 programs, each program can edit 40 steps | ||||||||

| Communication Portocol | MODBUS RTU Protocol, RS485 interface | ||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | ||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment,reactor material temp.(external temp. sensor) | ||||||||

| Expansion valve | Emerson thermal expansion valve/danfoss thermal expansion valve | ||||||||

| Evaporator | DANFOSS/KAORI Plate heat exchanger | ||||||||

| Operation Panel | 7-inch touch screen,show temp curve\EXCEL data output | ||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay,thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | ||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | ||||||||

| Refrigerant | R404A/R507C/R125/N40 All four refrigerants are available | ||||||||

QR code scanning

WhatsApp 086 13912479193

Wechat 086 15152266993

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA