ALL environmental test chambers model

GD -40℃~100℃

battery test chamber

Cooling capacity 1.8kW~15kW

Heating power 6KW~15KW

Temperature uniformity ±1℃

GD -80℃~150℃

climatic test chamber

Heating rate (+20~+150℃)A:5℃/min

Cooling rate Carrying idler (+20~-40℃)5℃/min

GD -40℃~180℃

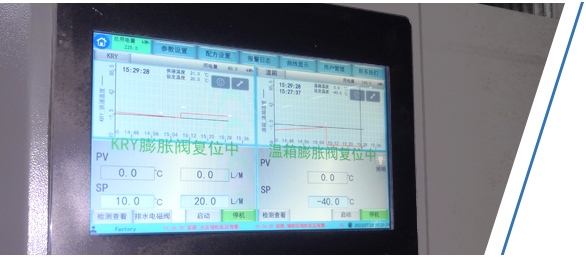

thermal shock chamber

Low temperature -40~0℃

High temperature +60~+150℃

Temperature fluctuation ≤1℃

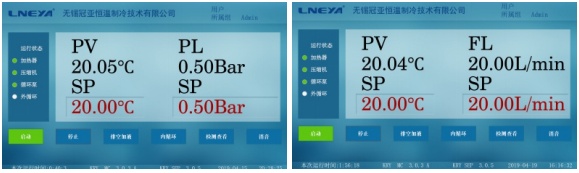

Industrial Chiller Heater Equipment Supplier-LNEYA

Industrial Chiller Heater Equipment Supplier-LNEYA